Sustainable Production Innovation

Toyota Burnaston brings circular production to life

Toyota's new dismantling plant at Burnaston uses Toyota Production System principles to process up to 10,000 end-of-life vehicles a year. This initiative is aimed at recovering materials and parts to improve sustainability.

Toyota Motor Europe has ignited a transformative shift in automotive sustainability with the launch of its first end-of-life vehicle dismantling plant. Announced two weeks ago by Leon van der Merwe, Vice President at Toyota Motor Europe, via LinkedIn, the facility became operational under the leadership of Ali Umit Sengezer, Head of CE, and Craig Marston, manager of Toyota’s Circular Factory, alongside their teams.

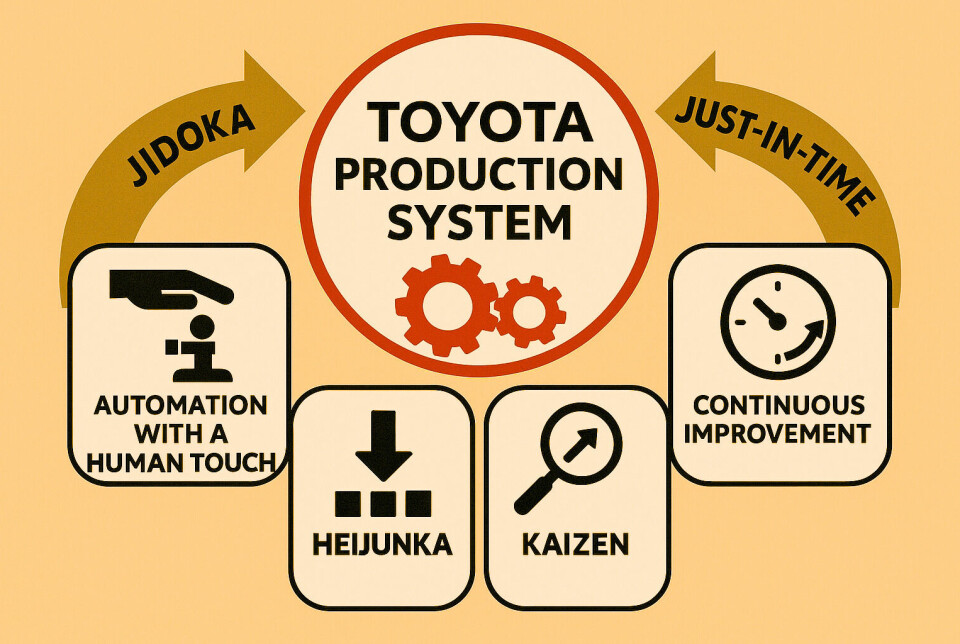

This milestone builds on the March unveiling of the Toyota Circular Factory (TCF) at Toyota Motor Manufacturing UK’s Burnaston plant, where it coexists with Corolla production. Amid thousands of dismantlers, Toyota stands out by applying Toyota Production System (TPS) principles in reverse, turning vehicle dismantling into a model of efficiency and circularity.

A distinctive dismantling vision

Surrounded by 1,000s of dismantlers, Toyota carves a unique path. “Today I am delighted to announce that Ali Umit Sengezer Toyota's Head of CE and Craig Marston our manager of Toyota’s Circular Factory with their teams, have taken our 1st end of life vehicle dismantling plant live, but there are 1,000’s of dismantlers so what make us unique,” van der Merwe posted.

He elaborated, “Firstly, our objective is not only to make money from selling used parts and scrap but to collect and deliver recyclable feedstock to our supply chain ensuring a clear pathway to achieving our goal of maximising car to car recycled materials into our next generation of vehicles.” This vision, first outlined in March, targets processing 10,000 vehicles annually, breathing new life into 120,000 parts and recovering 300 tonnes of high-purity plastic and 8,200 tonnes of steel, among other materials.

The Burnaston facility serves as a global centre of excellence, with plans to expand across Europe and collaborate with like-minded organisations. This aligns with Toyota’s carbon neutrality commitments: full neutrality by 2040, owned facilities by 2030, and a 100 per cent CO2 reduction in its European lineup by 2035. Operations began this quarter, marking a pioneering step within Toyota’s global network.

Inverting TPS for precision

Toyota reimagines TPS—celebrated for enhancing production efficiency—by applying it to dismantle vehicles. The plant runs an eight-pitch dismantling line at a fixed tact time, processing one car every three hours. “By applying ‘Just in time’ and Muda (waste) elimination we have dramatically reduced the space needed,” van der Merwe noted. Standardised work paves the way for kaizen, or continuous improvement, to increase profit and feedstock without added effort.

The jidoka philosophy—automation guided by human insight—refines processes before technology investment. “By following the Jidoka (automation with the human touch) mindset we are perfecting our processes before introducing technology, thereby reducing start-up capital investment,” he added. Safety is paramount: “We have the mindset of absolute safety, ensuring every one of our members goes home in the same condition he arrived at work.” This disciplined model, repeatable and scalable, aims to elevate the professionalism of the dismantling industry.

Strategic resource recovery

The TCF organises its efforts into three streams: reusable parts, remanufacturable commodities, and recyclable materials. Validated parts re-enter the market via retailers or distributors, while batteries and wheels are evaluated for remanufacturing or repurposing. Raw materials—copper, aluminium, steel, and plastic—are recycled to substitute virgin resources in new vehicles.

Van der Merwe’s March statement reinforces this strategy: “We initially anticipate recycling around 10,000 vehicles a year in our UK facility, which will give new life to 120,000 parts, recover 300 tonnes of high purity plastic and 8,200 tonnes of steel - amongst other materials.

As a next step for the Toyota Circular Factory concept, we plan to roll out similar operations across Europe. And we’re not stopping at our own facilities - we are eager to collaborate with other organisations who share our passion of circularity and commitment to carbon neutrality.” This precision transforms waste into a vital resource.

Industry-wide implications

As regulatory pressure on emissions and resource scarcity intensifies, Toyota’s model offers a blueprint. It mitigates raw material market volatility while advancing sustainability. Industry peers applaud the innovation. Rodney Naidoo, Head of Procurement & Supply Chain, Auto colours, commented, “This is a fascinating and impressive application of TPS principles. Applying Kaizen, Muda elimination, and standardised work to reverse logistics is a masterstroke in creating a sustainable, efficient circular economy.” Christopher Hug, Leading Expert in Circular Economy and ex-BMW added, “I am really curious to see whether Toyota’s example will catch on and whether we will see more dismantling factories in the future. Automated, AI-supported…”

Scaling across Europe requires navigating diverse regulations and forging partnerships. Van der Merwe’s call, “As I have said before, Toyota can’t do Circularity by our selves so please share or like this post,” invites collaboration that could standardise dismantling practices.

Toyota’s European presence

Toyota Motor Europe oversees sales, marketing, and manufacturing for Toyota, GR, and Lexus brands, employing over 25,000 people and investing EUR 11 billion ($12.9 billion, based on September 2025 rates) since 1990. Its eight plants in Portugal, the UK, France, Poland, Czech Republic, and Turkey support 16.5 million vehicles on European roads, served by 28 national companies and 2,800 retail outlets. In 2022, sales reached 1,080,975 vehicles, securing a 6.4 per cent market share.

The KINTO mobility brand, active in 14 countries, and zero-emission fuel cell products reflect Toyota’s “Mobility for All” ethos. Targeting 100 per cent CO2 reduction in new Western European vehicles by 2035, it offers a diverse electrified powertrain range.

A model for tomorrow

From its March announcement to its live launch, the TCF showcases Toyota’s leadership in sustainable manufacturing. By inverting TPS, it challenges the industry to rethink end-of-life strategies. Celso Yukio Eizak, Toyota Boshoku, Senior Manager, Production, Maintenance noted, “Great to see TPS applied in reverse! Bringing Just in Time, Jidoka, and Kaizen to vehicle dismantling shows how Lean thinking drives efficiency, safety, and sustainability—even beyond production.” For automotive professionals, this presents a compelling vision: circularity through precision and partnership.